轴头长度为什么比轴上零件宽一到二毫米

BSxxxccc2022-10-04 11:39:541条回答

BSxxxccc2022-10-04 11:39:541条回答

已提交,审核后显示!提交回复

共1条回复

因为爱你永不放弃 共回答了15个问题

因为爱你永不放弃 共回答了15个问题 |采纳率100%- 这样可以实现过盈紧密配合,如果不稍微大一些,就无法实现紧密镶套在一块,容易打滑和跑圈,造成轴头磨损.

- 1年前

相关推荐

- 英语翻译摘要本文主要是汽车前钢板弹簧前后支架底五孔钻孔多轴头组合机床设计,多轴头是一个带有多个输出的闭式传动箱,利用它可

英语翻译

摘要

本文主要是汽车前钢板弹簧前后支架底五孔钻孔多轴头组合机床设计,多轴头是一个带有多个输出的闭式传动箱,利用它可在立式钻床上进行钻孔、扩孔、绞孔和攻丝等工序加工.由于它的结构简单不需要改变既有机床设备,投资少、见效快因此适应中小批量多孔零件加工

汽车前钢板弹簧前支架底盖有4个Φ14.5的孔后支架底盖有3个Φ14.5孔需同时加工按工艺安排在Z535机床上用一夹具既要能加工前支架4个孔又能加工底盖上3个孔为节省更换多轴头所需的辅助时间故设计一套两种零件都能加工的通用多轴头.这两种零件形状和尺寸大致相同但也有不同处,故需设计一套夹具可以分别满足两种零件装夹和定位.

为提高工效需把普通钻头改成群钻,因此对刀具也要进行必要的设计.这样的结果节约了制造成本、保证了加工质量、提高了生产效率、增加了工人安全操作可靠性.

主要考虑并解决以下主要问题:(1)加工表面要求的精度和粗糙度;(2)工件的生产批量;(3)工件的结构形状和尺寸;(4)钻床改装的实际可能性.对被改装钻床的分析分析被改装钻床时包括的主要内容有:(1)分析机床能否适应改装要求;(2)调查和了解机床的使用情况;(3)考虑机床的动力情况;(4)分析改装后机床的强度和刚度问题.

【关键词】组合机床 多轴头 齿轮传动系统 群钻 钻模板 漫天红玫1年前1

漫天红玫1年前1 -

liuxiaomeng 共回答了16个问题

liuxiaomeng 共回答了16个问题 |采纳率93.8%the

This paper is mainly auto leaf spring before the before and after five hole drilling stent multiaxial head combination machine tools design, the multiaxial head is a multiple output with closed transmission box, can use it in the vertical drilling machine drilling, reaming, wring holes and tapping the process such as processing. Because of its simple structure don't need to change both machine tool equipment, less investment, quick effect so adapt to small and medium-sized batch porous parts processing

Auto leaf spring before before four base of support Φ 14.5 after the hole of the base of support 3 Φ 14.5 hole shall also processing according to the arrangement of technology in Z535 with a fixture on the machine can not only four holes before processing stent and processing base for three holes to save more for replacement shaft head auxiliary time reason design a set of two parts will be the multiaxial head processing general. The two parts in shape and size of roughly the same but also have different place, reason need to design a fixture can meet the two parts are clamping and positioning.

In order to improve the efficiency of the common to drill to drill, so the tool will make the necessary design. The results of the production cost saving, that ensure the process quality, improve the production efficiency, increase the workers' safety operation reliability.

The main consideration and solve the following main problems: (1) processing surface requirements of precision and roughness; (2) the production batch; (3) the shape and size of workpiece structure; (4) drilling machine refitted practical possibility. The analysis of the drilling machine be modified to be modified analysis when the main content of the drill include: (1) to analyze the machine is ready to adjust to modified requirements; (2) to investigate and understand the use of machine tools; (3) considering the power of machine tools; (4) analysis modified strength and stiffness of the machine tool.

【 key words 】 combination machine tools multi-axis head gear transmission system group of drill drill template1年前查看全部

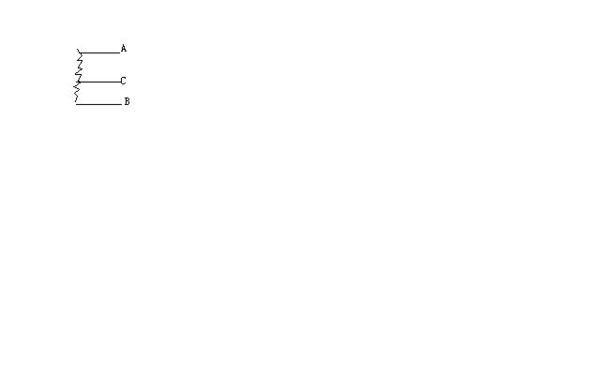

- 一电烙铁的电热丝上有中心轴头C,已知在AB两端加上220伏电压时,电烙铁的功率是150瓦,若将A和B 相连接,在Ac两端

一电烙铁的电热丝上有中心轴头C,已知在AB两端加上220伏电压时,电烙铁的功率是150瓦,若将A和B 相连接,在Ac两端加上110伏的电压,则电烙铁的功率是

笨笨_猫1年前3

笨笨_猫1年前3 -

INTER1985 共回答了12个问题

INTER1985 共回答了12个问题 |采纳率100%首先A、B未联时,P=U^2/R,此时整个电阻阻值为R,电压为U

当A、B相连,AC段与BC段形成并联,而AC段与BC段每段阻值为R/2,并联之后整个电路阻值为R/4,

而电压为110V,即U/2,因此,后来的功率P1=(U/2)^2/(R/4)=U^2/R.说明此时功率与之前相等,即150W.1年前查看全部

- 钳工用丝锥的材料一般为( )?A、轴环 B、轴肩 C、轴颈 D、轴头

engfpj1年前1

engfpj1年前1 -

湖海相连 共回答了26个问题

湖海相连 共回答了26个问题 |采纳率88.5%40CrMo1年前查看全部

- 轴头机械基础的题

carina_wu1年前1

carina_wu1年前1 -

gllgoe 共回答了20个问题

gllgoe 共回答了20个问题 |采纳率95%轴的两端部分通常称为轴头.轴头部分的作用通常是安装轴承,起到承载轴上设备运转的作用.

希 望 能 够 帮 到 您,望 采 纳!1年前查看全部

- 电位器中心轴头于总电阻的每个角之间有电阻吗?

商州狼1年前1

商州狼1年前1 -

cupidsuhe 共回答了14个问题

cupidsuhe 共回答了14个问题 |采纳率78.6%一般对电阻体是镀膜方式的电位器而言是肯定的(两个端头处附近则不一定).但对线绕电位器,因为内部机构原因,每个角度间会有电阻,但不一定不同,电阻值也可能不连续,这一点你拆开线绕电位器看一看便可明白.1年前查看全部

大家在问

- 18y-3(3y+2)=6解方程,

- 2如何把气体转化为液体

- 320012001÷19971997.

- 4老师 求解答一个证明题 设n维基本向量组可由n维向量组线性表示,证明n维向量组线性无关

- 5某站有甲、乙两辆汽车,若甲车先出发1h后乙车出发,则乙车出发后5h追上甲车;若甲车开出30km后乙车出发,则乙车出发4h

- 6如果两个三菱锥 已知一个三角形相等 一条线相等 能否说两个三角体 体积相等?

- 7等比数列{an}中,a5=4,a7=6,则a9=______.

- 8集合M={0,1},N={y 竖线 x的平方+y的平方=1,x属于N}则M,N的关系是M真包含于N.

- 9任意n+1个n维向量必线性任意n+1个n维向量必线性

- 10在一幅标有如下比例尺的地图上,量的铁路线上甲、乙两站之间的距离是16厘米.客车和货车同时从甲乙两地相向而行,客车每小时行

- 11毛毛剌剌中剌的拼音是什么

- 12怎么交朋友?再过九天我就要读初一了,我想在刚开学那几天就可以交到朋友,但要怎么交呢?难道要,开学第一天,走到人家面前,说

- 13小学培优题(一定要详细,不然不给分)(1)甲、乙两人步行速度之比是7:5,甲、乙分别由A、B两地同时出发,如果相同而行,

- 14如何证明一个命题是真命题呢?下面几个人的说法是否正确?

- 15已知p是双曲线x^2/a^2+y^2/b^2=1右支上一点,F1 F2分别是双曲线的左右焦点,I为三角形PF1F2内心,