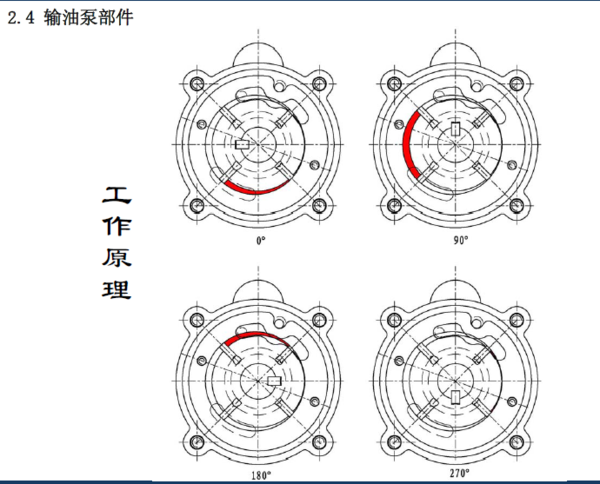

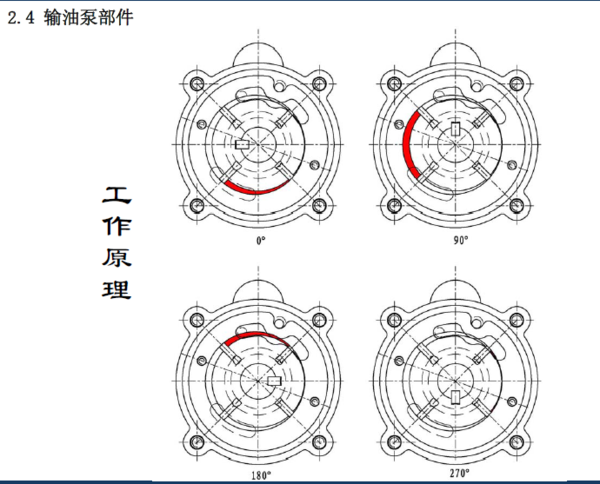

叶片式输油泵的原理是什么?如图,实在是看不懂.

米虾虾2022-10-04 11:39:541条回答

米虾虾2022-10-04 11:39:541条回答

叶片式输油泵的原理是什么?

如图,实在是看不懂.

如图,实在是看不懂.

已提交,审核后显示!提交回复

共1条回复

24km 共回答了20个问题

24km 共回答了20个问题 |采纳率85%- 首先你要知道油泵壳体与转子是偏心安装的,图中的中心点是针对转子而言.进油口在偏心的一端,出油口在另一端.当转子旋转时,叶片被甩出,紧贴壳体内腔形成密封空腔.0——90这一段,叶片隔出的空腔在增大,形成负压,油被吸进.再转90度,接近偏心的另一端,叶压隔出的空腔在变小,压力增大,油被压出.这就是叶片泵的泵油原理.如果偏心距可调,则为输出压力可调叶片泵.当然,如果转子与壳体没有偏心距,则无法泵油.

- 1年前

相关推荐

- 英语翻译请大虾们帮忙把下面的短文译成英文,急用!离心泵是叶片式流体机械的典型产品.其特点为:转速高,体积小,重量轻,效率

英语翻译

请大虾们帮忙把下面的短文译成英文,急用!

离心泵是叶片式流体机械的典型产品.其特点为:转速高,体积小,重量轻,效率高,流量大,性能平稳,容易操作和维修等.在国民经济的许多部门,离心泵都扮演着重要角色.

本文根据给定的泵的技术指标,利用经验数据并参考了大量的设计实例,对题目要求的节段式多级离心清水泵进行了总体设计.其中叶轮的水力设计是最关键的设计之一,本设计参考一些具有良好水利性能的泵,选取合适的系数,使其达到良好的水利性能;平衡装置采用平衡盘,装置简单可靠,能够较好地平衡轴向力;密封装置采用毛毡圈,经济实用.最后,对离心泵的某些部件进行了校核计算,其中包括键槽,主轴,拉紧螺栓等关键部位、部件.此外,设计尺寸留有大量余量,保证了该离心泵具有较长使用寿命和较大的改进空间.

关键词 离心泵;叶轮;平衡盘;水力设计;校核

另:译的好,我一定会追分的! agwanghui0011年前1

agwanghui0011年前1 -

wugang1293 共回答了15个问题

wugang1293 共回答了15个问题 |采纳率80%Leaf-centrifugal pump is a typical fluid machinery products.Its characteristics:high-speed,small size,light weight,high efficiency,flow,simple structure,performance,smooth,easy operation and maintenance.In the national economy in many sectors,centrifugal pumps have played an important role.

According to the pump given the technical indicators,using data and information and experience in the design of a large number of examples,the subject of the requirements of section struts multi-stage centrifugal pumps to clear the overall design.One of the impeller hydraulic design is one of the most critical design,the reference design some of the good performance of water pumps,select the appropriate factor to achieve good performance of the water; balance installations in balance disc,the device is simple and reliable,better able to Balance axial force,sealing devices used blankets laps,economical and practical.Finally,the centrifugal pump some parts of the check,including the key slot,spindle,tighten bolts and other key parts and components.In addition,the design of large size have a cushion to ensure that the centrifugal pump with a longer service life and greater room for improvement.

Keywords centrifugal pump; impeller; balance disc; hydraulic design; Checking1年前查看全部

大家在问

- 1小明怎么样? 翻译()()Xiao Ming. 求帮助.

- 2there are two pumpkins I want 什么 one A big B bigger C the bi

- 3根据所给提示写一篇题为“My English teacher”的短文,70词左右。

- 4已知二次函数f(x)=ax²+bx+c满足f(1)=1,且f(-1)=0 1)

- 5如图,在三角形纸片(△ABC)中,∠A=90°,AB=3,BC=5,按图示方式进行折叠,使点B落在边AC上,记为点B

- 6我会照样子写句子. 我会照样子写句子.1.我把小熊当成学生给他上课.我把______________当成________

- 7(2011•嘉兴)目前“自驾游”已成为人们出游的重要方式.“五一”节,林老师驾轿车从舟山出发,上高速公路途经舟山跨海大桥

- 8英语翻译thank youfor always being so supportive and kindyour fri

- 93*x/3*x乘号可以省略吗?

- 10EXCEL中如何找出与A:A=5,A+1:A=3,A+2:A=9这相邻三行相同排列数的其他的相邻三行

- 11are these___?yes,they are.怎么回答

- 12when i'm 4 years old为什么加years old 而at the age of 4不加years ol

- 13有一筐苹果,卖出[1/4]后,又卖出4千克,这时还剩16千克,这筐苹果原有______千克.

- 14写一个有关“人生”与“快乐”的比喻句

- 15on no occasion must you accept the money if he offers .是不是译为