均化溶剂``区分溶剂,

t284kk12022-10-04 11:39:541条回答

t284kk12022-10-04 11:39:541条回答

已提交,审核后显示!提交回复

共1条回复

qq7895 共回答了20个问题

qq7895 共回答了20个问题 |采纳率85%- 将各种不同强度的酸均化到溶剂合质子水平的效应叫均化效应,

具有均化效应的溶剂称为均化溶剂

能区分酸(碱)强弱的效应称为区分效应.

具有区分效应的溶剂叫区分溶剂 - 1年前

相关推荐

- 英语翻译注塑机注塑原理:一,把原料固体粒料经过料筒中加热、输关、压实、剪切、混合、使熔体的温度均化、黏度均化、密度均化和

英语翻译

注塑机注塑原理:

一,把原料固体粒料经过料筒中加热、输关、压实、剪切、混合、使熔体的温度均化、黏度均化、密度均化和物料组分均化,使物料从玻璃态经过黏弹态转变为黏流态.

二,在原料塑化过程中要完成注射前的计量程序,由於聚合物的热机特性决定了预塑过程是热能输入和转换过程,预塑过程的热能的输入方式如下:

1.料筒通过电热元件加热,料筒中的物料通过热传导吸收外部供热使其软化和熔融.

2.物料靠螺杆旋转使机械能转变为热能,通过剪切机理和磨擦机理,加热自身,使其熔融.

3.物料加热通过1、2方式的结合.料筒中物料的塑化一部分靠外部传导热,另一部分靠螺杆旋转的剪切能量来控制物料的塑化过程和塑化质量.

三,注塑充模:注射充模阶段是螺杆在注射油缸推力作用,将储料室中的熔体经过喷嘴、模具流道、浇口注入型腔.注射时,在螺杆头部熔体所建立起来的压强称注射压力;螺杆推进熔体的速度称注射速度,其流率称注射速率;其行程称注射行程,在数值上与预塑行程与称计量行程相一致.在注射阶段,必须使熔体建立足够的速度头和压力头,才能完成好充模过程,保证制品质量.

四,保压补缩:注射阶段完成后,必需经过继续保持压力作用下,模腔中的熔体得到因冷却而补缩,制品得到压缩与增密.保压压力,可以维持原来的注射压力(一次注射压力),也可以降低可提高原来的注射压力,形成二、三级或多级压力.保压阶段的特点是熔体在高压下的慢速流动,螺杆有微小的补缩位移,物料随冷却和密度增大使制品逐渐成型,保压压力持续到浇口冻封为止. OPS膜拜LZ1年前5

OPS膜拜LZ1年前5 -

long800129 共回答了19个问题

long800129 共回答了19个问题 |采纳率89.5%Casting machine casts the principle:

One,heats up the raw material solid process material tube in,loses the pass,the compaction,cuts,the mix,causes to melt the bodythe temperature equalization,the viscosity equalization,the densityequalization and the material component equalization,causes thematerial to mount the ball condition transformation from the glasscondition process for to mount the fluid state.

Two,must complete before the injection in the raw materialplasticizing process the measurement procedure,because the polymerheat engine characteristic had decided models the process is inadvance the heat energy input and the switching process,models theprocess in advance the heat energy input way as follows:

1.The material tube heats up through the electric heating part,expects in the tube the material to absorb exterior heating throughthe heat conduction to cause it to soften and to fuse.

2.The material depends on the screw rod to revolve causes themechanical energy to transform into the heat energy,through cuts themechanism and the friction mechanism,heats up oneself,causes it tofuse.

3.The material heats up through 1,2 ways union.In exterior thematerial tube a material plastified part depends on passes on the heatconduction,another part depends on the screw rod to revolve cuts theenergy to control the material the plastified process and theplastified quality.

Three,casts the sufficient mold:Injects the sufficient mold stage isthe screw rod in the injection cylinder thrust force function,ChuLiaoshi in melt body after spray nozzle,mold flow channel,pouring into cavity.When injection,establishes the intensity ofpressure in the screw rod forehead melt body to call the injectionpressure; The screw rod advances the melt body the speed to call theinjection speed,its calls the injection speed; Its travellingschedule called the injection travelling schedule,with models thetravelling schedule in the value with to call in advance themeasurement travelling schedule is consistent.In the injection stage,must cause the melt body establishment enough speed and the pressurehead,can complete the sufficient mold process,the guarantee productquality.

Four,guarantees the pressure to make up shrinks:After the injectionstage completes,the essential process continues to maintain under thepressure function,in the cavity melt body obtains because of coolsmakes up shrinks,the product obtains the compression with to increasedensely.Guarantees presses the pressure,may maintain the originalinjection pressure (an injection pressure),also may reduce mayenhance the original injection pressure,forms two,three level or themultistage pressure.Guarantees presses the stage the characteristicis melts the body to flow under high pressure idling speed,the screwrod has small makes up shrinks the displacement,the materialincreases ambassador along with cooling and the density the productgradually to take shape,guarantees presses the pressure to holdarrives in succession frozen seals up to.1年前查看全部

- (1/2)吹瓶PE料 模头温度170.均化段170.压缩段165-180.入料段180-190 这样可以吗 然后口模温度

(1/2)吹瓶PE料 模头温度170.均化段170.压缩段165-180.入料段180-190 这样可以吗 然后口模温度该...

(1/2)吹瓶PE料 模头温度170.均化段170.压缩段165-180.入料段180-190 这样可以吗 然后口模温度该怎样控制才 nlorraine1年前1

nlorraine1年前1 -

岑林 共回答了14个问题

岑林 共回答了14个问题 |采纳率92.9%入料段我觉得温度高了点,口模温度是看你生产时去顶.温度设置要根据吹瓶机及产品要求的大小去定1年前查看全部

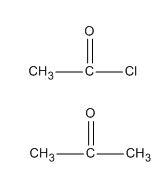

- 上面的C=O伸缩振动肯定比下面的大,原因我知道但是我想问,Cl不是还可以和C=O形成p-π共轭,会均化双键吗?敬请高手回

上面的C=O伸缩振动肯定比下面的大,原因我知道

但是我想问,Cl不是还可以和C=O形成p-π共轭,会均化双键吗?

敬请高手回答,一般高手勿答.我想要真正正确的答案,不是猜测之类的 雅痞198207271年前2

雅痞198207271年前2 -

zhujd_sh 共回答了18个问题

zhujd_sh 共回答了18个问题 |采纳率83.3%氯的吸电子作用强于p-π共轭,所以受吸电子的影响为主.1年前查看全部

- 逻辑表达式为什么一般均化为与非门的形式

飞水流云1年前1

飞水流云1年前1 -

爱上大只猪 共回答了14个问题

爱上大只猪 共回答了14个问题 |采纳率85.7%因为在CMOS应用中,NOR和NAND只需4个MOS即可制造,占用面积较小.例如NOR,上面(逻辑1,接VDD)两个PMOS串联,下面(逻辑0,接地)两个NMOS并联.另外,在有些高级MOS应用中,例如CVSL,多米诺门等等,输出自己就含有正反两个逻辑(即有两个输出端,使得一个逻辑门可以实现NOR/OR门的效果),可以根据情况取用.1年前查看全部

大家在问

- 1分别用景仰、唐突、顶礼膜拜、静默、恬静、由衷、震颤、神秘莫测造句

- 2它的水很清澈有很多小鱼在下面游翻译成英

- 3设loga(X)=logb(Y)=2,a+b=2,则X+Y取值范围为?

- 4(2012•鞍山一模)游泳时,使人向前行进的力的施力物体是( )

- 5商务谈判的六种结果是什么是商务谈判实务第五章简答题第三题

- 6碳酸电离一个氢离子,就是一个氢离子参加反应,生成碳酸氢盐,电离两个就是两个参加反应,生成碳酸盐

- 7关于磁感线,下列说法中正确的是( ) A.磁感线是实际存在于磁场中的线 B.磁感线上任意一点的切线方向,都跟该点的磁场

- 8关于有机化学中的烯醇式的知识

- 9If you work hard,you will make a great _____.所填单词以S开头

- 10在下列句子中填入表示声音的词1、教室里传来朗朗的读书声2、豆大的雨点打在玻璃上()直响3、“()”这是夏天打雷的声音4、

- 11The Most Useful Invention of All Time

- 12X平方加2X加1等于2X平方加X

- 132*√15约等于多少?(保留四个有效数字)2*3次√14呢?

- 1430以内的合数有哪些

- 15写一篇关于雾霾成因和影响的作文